Loading arms

We supply loading arms and related equipment for the transfer of fluids or gases from storage tanks to mobile tanks, by road, rail or sea.

Our top, bottom and marine loading arms improve safety and reduce condensate losses at site compared to the use of hoses.

Top loading arms feature robust and high-quality swivel joints and spring cylinder balancing for comfortable and smooth handling.

The advantages in comparison with hose loading facilities are:

- Ease of handling.

- Higher availability/flexibility.

- Less man-power and minimum maintenance.

- Maximum operational safety and minimized operational cost (cost of ownership).

Added value

Safe

Installation

Versatile

Technical expertise

Product selection

Top loading arms

Top loading arms remain the most popular method of filling tank vehicles in the world.

Depending on the need, there are different types:

- Short range when the vehicle can be positioned accurately.

- Variable radius which allows greater coverage of load points.

- Long range which allows maximum coverage of the loading points.

We provide top loading arms and equipment including manhole covers, emergency valves, pressure vents, for a broad range of chemical, petrochemical, pharmaceutical and food and beverage applications.

We can also provide information and support on converting from top to bottom loading.

- Designed to load or unload drums, barrels or IBC containers.

- Long reach suitable for applications where the manhole or the connection flange cannot be positioned accurately.

- Can be fixed in the working position, preventing it from slipping off the manhole.

- Meets International Petroleum Industry requirements. Due to the standardised design, it is the most economical solution for this application.

- Designed for the top loading of road or rail tankers via a manhole.

- Designed for loading/unloading of acids and caustics (e.g. 33 % hydrochloric acid, 30 % sulphuric acid etc.).

- Suitable for closed and open top loading/unloading of road and rail tankers with flange connection or cone. The closed system prevents the escape of poisonous and aggressive vapour.

- Long reach suitable for applications where the tanker connection flange cannot be accurately positioned.

- An inlet flange can be included in down stream designs and alternative variations of the loading arm are possible.

- Other loading arm variants can be provided with PTFE lining as required.

Bottom loading arms

Bottom loading is one of the most common methods used to transfer product into road or rail tankers.

Since bottom loading takes place on the ground it is inherently safer for the operator than top loading. In addition, less static electricity is generated than through top loading, allowing for faster and more efficient loading.

In the case of modern fuel terminals, multiple compartments of road tankers can be filled at the same time.

We provide bottom loading arms and equipment for a broad range of chemical, petrochemical, pharmaceutical and food and beverage applications.

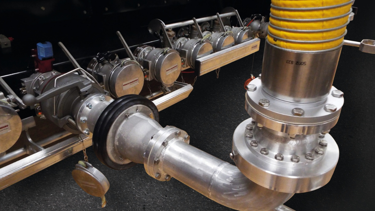

Marine loading arms

We supply marine loading arms for loading or unloading almost all liquid products and compressed gases from river barges, ships and ocean-going super tankers. With manual or hydraulic controls, they have the same functionality as the other arms but need a more complex design to ensure safety.

The design allows the arm to be assembled so that it follows the movement of the sea. This ensures that it is always paired with the boat without damage and for safe transfer.

- Used to display the position of the marine loading arm within its defined operating envelope. The display uses a standard industry PC and is a live feed of the actual position of the marine loading arm.

- Remote maintenance.

- Display redirection via TCP/IP or modem.

The PMS is a stand alone unit and works in the following way:

- A pendulum potentiometer located on the inboard arm measures the angle of the inboard arm with respect to vertical.

- A pendulum potentiometer located on the outboard arm measures the angle of the outboard arm with respect to vertical.

- A direct coupled potentiometer located at the base riser swivel joint measures the slewing angle.

- Information from the potentiometers is relayed through a PC hooked to the local control panel.

You might also be interested in...

Couplers

Loading systems

Metering systems

Here to help with seamless delivery and management of your next process industry project.

Our experts are available to advise, support, and assist with any issues relating to your storage tanks and liquid process infrastructure ensuring you have a safe site, prevent any pollution, and remain operational.

Speak to our experts