Bespoke engineered maintenance solutions

In industrial processing, the adverse impact of neglecting routine maintenance and servicing on the efficiency of equipment is a well-acknowledged problem. Businesses often experience a notable decline in equipment effectiveness, leading to diminished productivity and escalated costs due to increased susceptibility to downtime and breakdowns resulting from inadequate maintenance.

When deploying your bespoke equipment on-site, we undertake a thorough assessment of your requirements and propose a tailored servicing package. This bespoke approach ensures that your equipment consistently operates at its optimum capacity, maximising its lifespan potential.

All our maintenance and servicing packages are crafted to suit the distinct needs of each customer and their specific business processes. Recognising that every business has unique requirements, we emphasise the importance of a customised maintenance and service plan that addresses individual compliance and business continuity needs. We also consider the diversity in equipment and processes across different sites, and tailor our approach to accommodate the specific characteristics of each company.

To determine the optimal frequency and duration of visits, we rely on Original Equipment Manufacturer (OEM) recommendations and leverage usage data, fed into a risk-based analysis process. This comprehensive approach enables us to deliver an effective maintenance solution tailored to your equipment and operational needs.

You might also be interested in...

Storage tanks

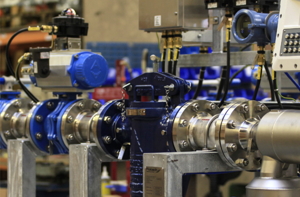

Pipework

Flow engineering

Here to help with seamless delivery and management of your next process industry project.

Our experts are available to advise, support, and assist with any issues relating to your storage tanks and liquid process infrastructure ensuring you have a safe site, prevent any pollution, and remain operational.

Speak to our experts